[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

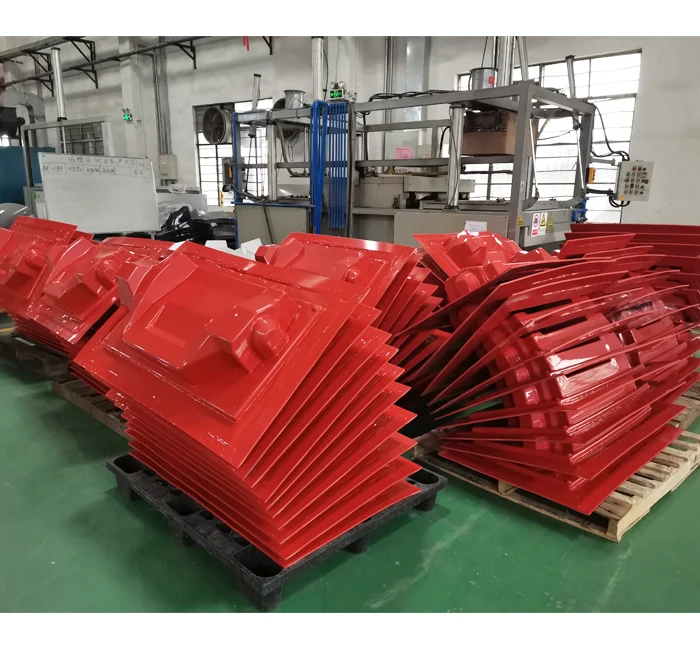

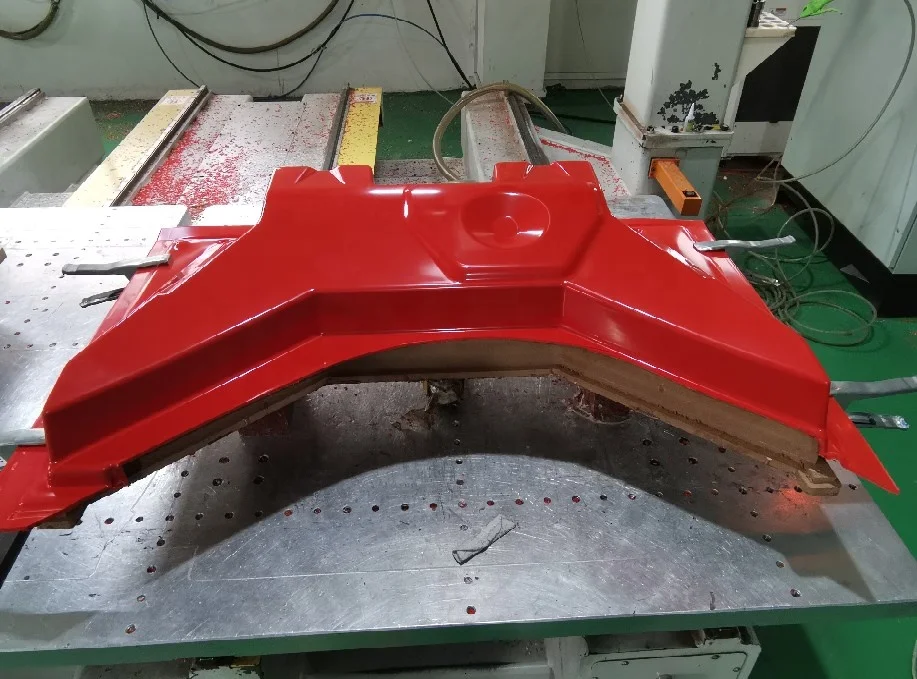

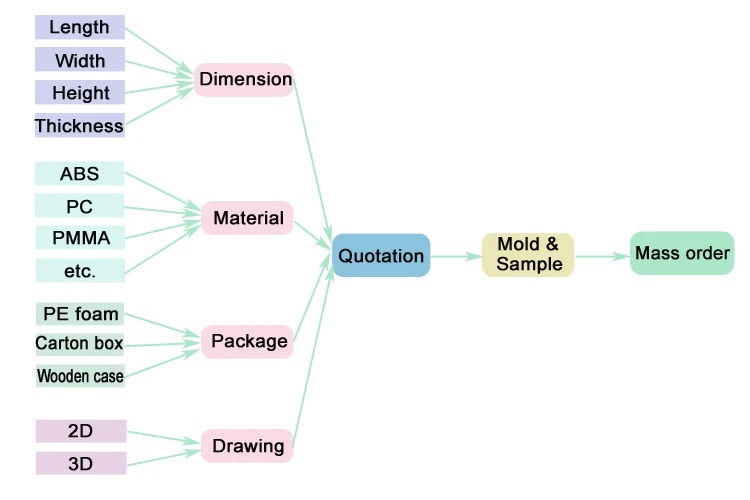

名前 | カスタム真空熱成形部品 |

素材 | Abs、pet、pc、pp、pmma、ps、PVCなど |

サイズ | 最大l4.5m * w2.5m * h1.2m (1 ~ 12mm) |

型 | アルミ型 |

Moq | 50個、サンプル注文可能です。 |

仕上げ | 滑らか、光沢、塗装など |

配送 | 海、空または電車で配達。 |

Uasge | 新しいプラスチック製品の研究開発 |

Cooig.com で行われるお支払いはすべて厳格な SSL 暗号化と PCI DSS データ保護プロトコルで保護されています

ご注文品が出荷されていないか、行方不明になっている場合、または製品に問題がある場合は返金を請求してください。不良品の現地での返品は無料です。