Iをクリックします。 特性

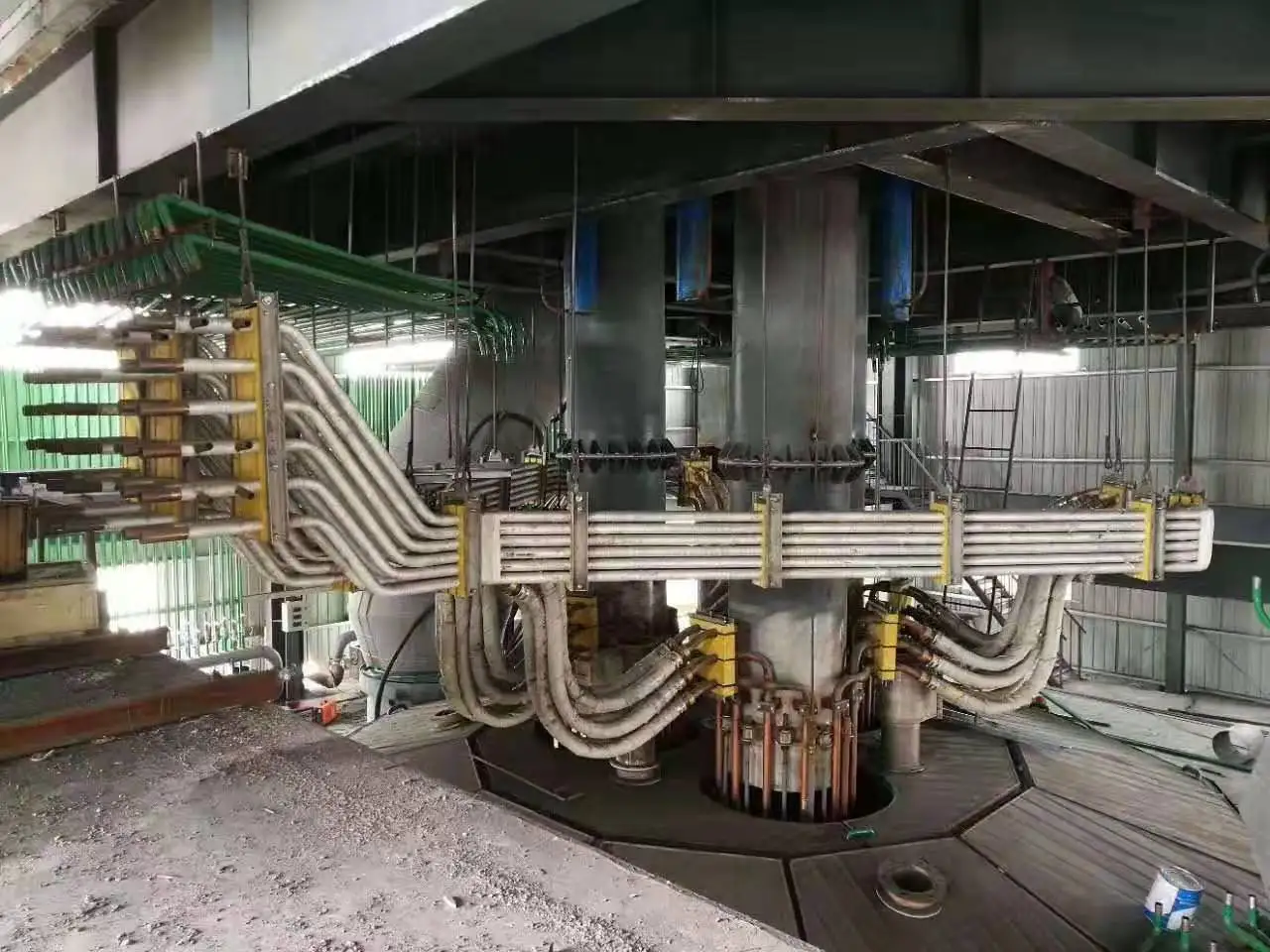

1.高温耐性* 冶金工業用電気炉の短いネットワークは非常に高い

動作中の温度 短いネットワーク絶縁材料は高温環境に耐えることができます。 高温耐性は主に、急速な老化、分解、または絶縁特性の損失なしに、数百 ℃ 以上の温度に長時間さらされる可能性があることで現れます。 たとえば、セラミック繊維部品を含む絶縁材料の中には、1000 ℃ を超える耐熱性があり、冶金電気炉ショートネットワークの高温作業条件に効果的に適応できます。

* これらの材料は高温でも良好な熱安定性を維持し、熱膨張係数が比較的低くなります。 これは、温度が変化しても、過度の膨張や収縮による亀裂や損傷がないため、断熱の継続性と信頼性が確保されることを意味します。

2.高い絶縁強度

* 冶金電気炉ショートネットワークの電流は通常非常に大きくなります。 したがって、絶縁材料は電流漏れを防ぐために高い絶縁強度を持たなければなりません。 絶縁抵抗は非常に高く、破壊されることなく数千ボルト以上の電圧に耐えることができます。 たとえば、マイカテープやその他の絶縁材料の絶縁耐力は10〜50kv/mmです。これにより、高電圧環境で電流を効果的に遮断し、ショートネットワークシステムの安全な運用を確保できます。

* それらはまた低い絶縁損失を持っています。 交流電界の作用下では、電力損失は小さく、電気炉のエネルギー利用効率を向上させ、絶縁材料自体の損失によって発生する熱を低減するのに役立ちます。

3.優れた機械的特性

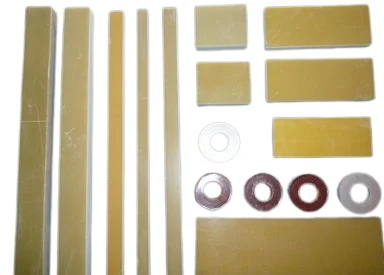

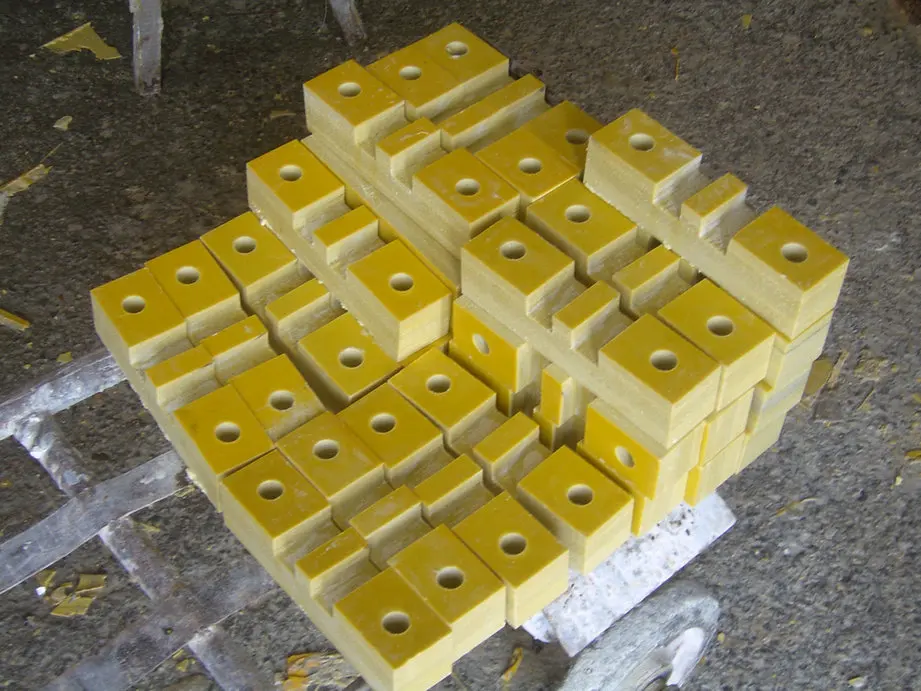

* ショートネットワーク絶縁材料は、設置時のストレスや、動作中に受ける可能性のある振動や衝撃などの外部の力に耐えるのに十分な機械的強度が必要です。 例えば、エポキシ樹脂ラミネート製品の中には、引張強度と曲げ強度が比較的高いものがあります。 引張強度は30〜100mpaに達し、曲げ強度は50〜150mpaに達します。

* これらの材料もある程度の靭性を持ち、壊れにくいです。 複雑な機械環境での整合性を維持できるため、断熱効果の耐久性が保証されます。

4.化学的安定性

* 金属など、冶金産業環境にはさまざまな化学物質が存在する可能性があります酸化物および腐食性ガス。 短いネットワーク絶縁材料は、これらの化学物質に対する耐性が高く、耐薬品性。 たとえば、ポリマー絶縁製品は、特定のPh範囲3 ~ 11で安定したパフォーマンスを維持します。

* また、冶金プロセス中に発生するほこりや油などの汚染物質の付着や浸食に抵抗し、断熱性能に影響を与えません。

5.アーク抵抗* アーク現象は、冶金電気炉ショートネットワークの動作中に発生する可能性があります。 絶縁材料は耐アーク性に優れており、損傷することなくアークの衝撃に耐えることができます。 たとえば、特殊な配合の絶縁材料の中には、アークの作用下で保護膜をすばやく形成して、アークのさらなる浸食を防ぎ、ショートネットワークシステムの安全性を保護するものがあります。

Ii.利点

1.安全保証

* 高い絶縁強度や耐アーク性などの特性により、短絡や漏れなどの電気事故の発生を効果的に防止し、オペレーターの個人的な安全と正常性を確保します冶金電気炉設備の操作 高エネルギーおよび高リスク環境での冶金信頼性の高い絶縁材料は、安全な生産のための重要な要素の1つです。

2.高効率と省エネ

* 低絶縁損失の特性は、絶縁体の電力損失を減らすのに役立ちます

電気炉のエネルギー利用効率を向上させます。 冶金業界のような大規模なエネルギー消費者にとって、これは生産コストを削減し、経済的利益を改善することができます。 同時に、良好な熱安定性は、電気炉のショートネットワークの正常な動作温度を維持し、異常な温度によって引き起こされるエネルギーの無駄を減らすのにも役立ちます。

3.強い耐久性

* 高温耐性、優れた機械的特性、化学的安定性により、絶縁材料の寿命が長くなります。 これは、冶金電気炉の長期運転中に絶縁材料を頻繁に交換する必要がないことを意味し、装置のメンテナンスコストとダウンタイムを削減し、生産効率を向上させます。

4.幅広い適応性

* これらの絶縁材料は、さまざまなタイプの冶金電気炉に適応できます。アーク炉、誘導炉または他の特殊な電気炉、適切な絶縁材料を選択することができます特定の作業条件と要件に応じて さらに、彼らはまた異なったとうまく協力することができますショートネットワークシステムの全体的なパフォーマンスを最適化するための金属材料およびその他のコンポーネント