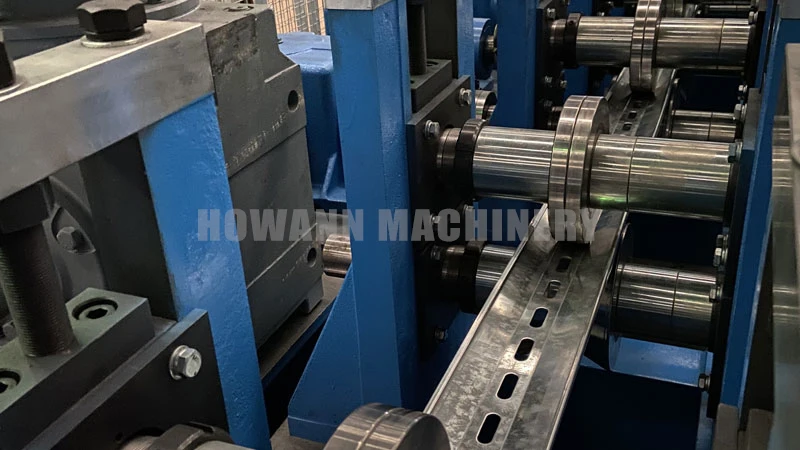

Roller material:

Hardwood plated on the surface

High hardness roller

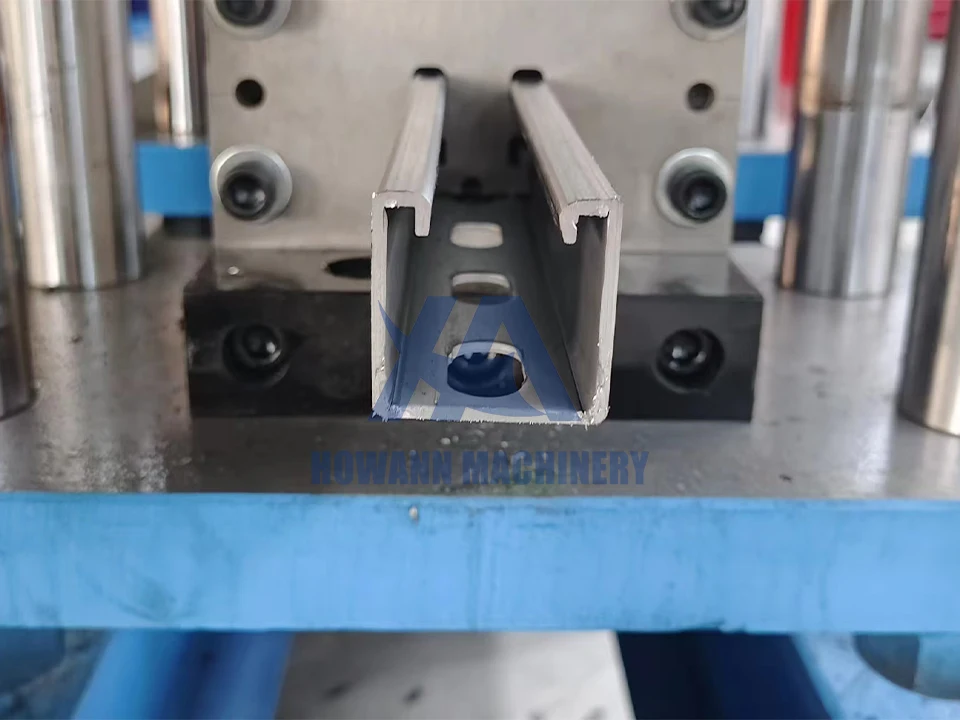

High-precision machining rollers Does not hurt the galvanized surface of the profile

High-precision machining rollers Does not hurt the galvanized surface of the profile

高精度ユニストラットソーラーストラットチャンネルソーラーパネル製造機ソーラーストラットロール成形機スチールフレーミング機

高精度ユニストラットソーラーストラットチャンネルソーラーパネル製造機ソーラーストラットロール成形機スチールフレーミング機

無償交換部品

無償交換部品

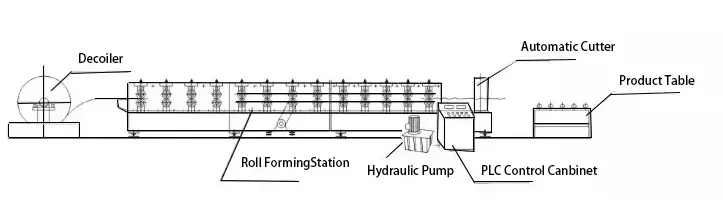

Photovoltaic bracket production line configuration components | ||||

Name | Quantity | Units | ||

Double head hydraulic uncoiler | 1 | Set | ||

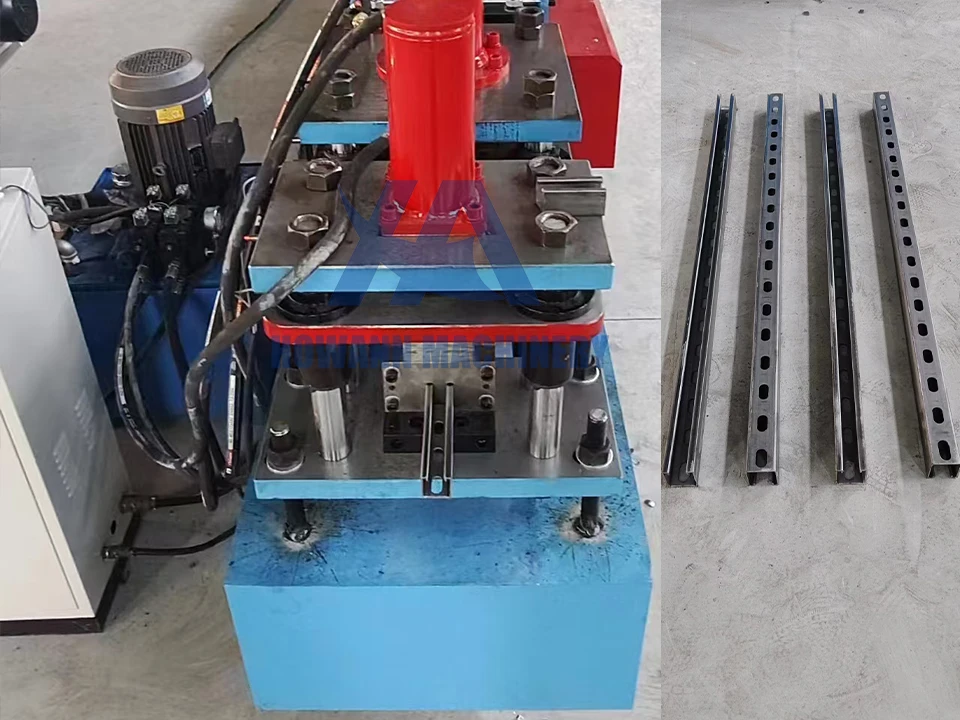

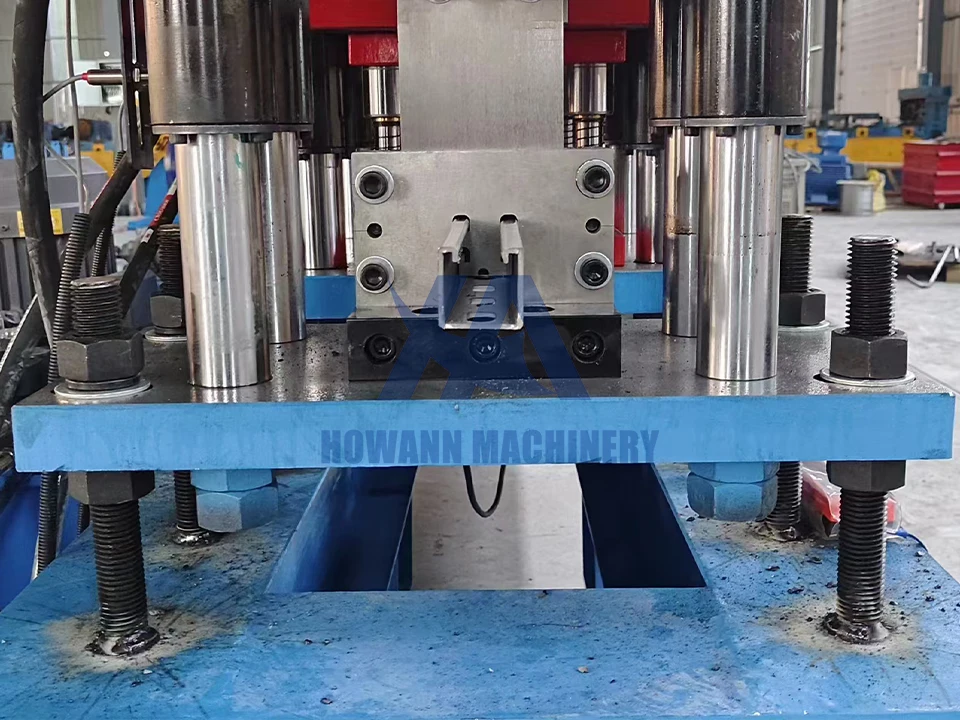

Rotary punching device(Maximum speed 80m/min) | 1 | Set | ||

Siemens motor drive | 1 | Set | ||

Adjustable feeding platform | 1 | Set | ||

Roll forming system | 1 | Set | ||

Non-stop cutting | 1 | Set | ||

Hydraulic system | 1 | Set | ||

Delta PLC electronic control system | 1 | Set | ||

Supporter/Automatic Stacker | 1 | Set | ||

Cooig.com で行われるお支払いはすべて厳格な SSL 暗号化と PCI DSS データ保護プロトコルで保護されています

ご注文品が出荷されていないか、行方不明になっている場合、または製品に問題がある場合は返金を請求してください