[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

無償交換部品

無償交換部品

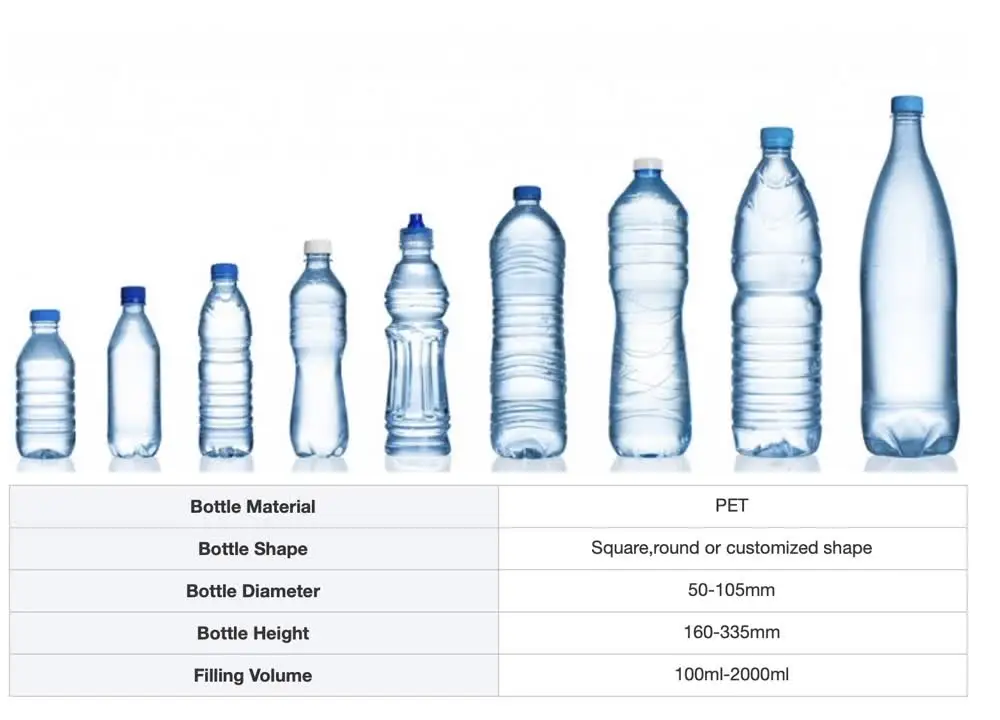

Containers and Specifications | ||||||||

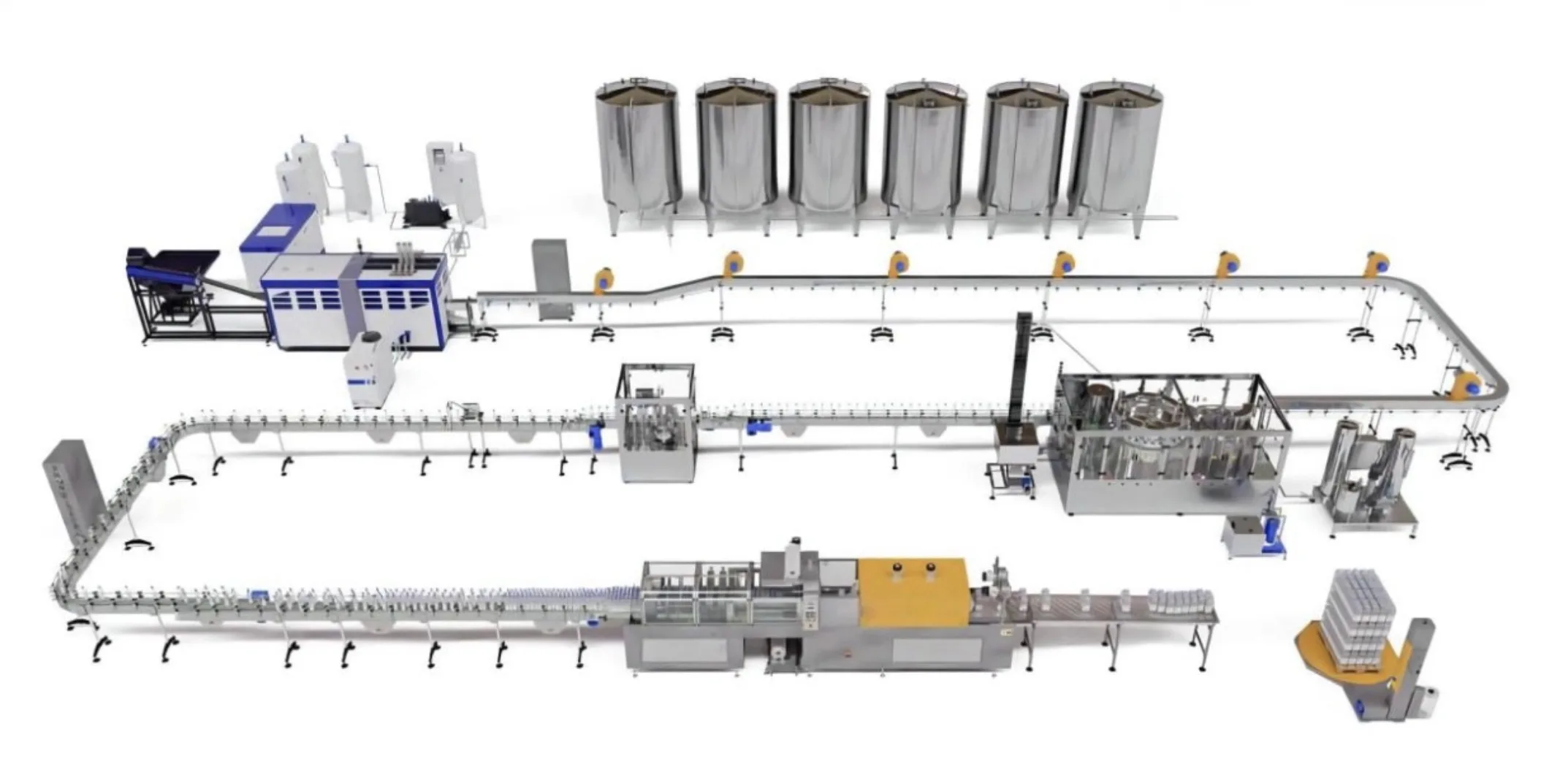

Project Name: Full Automatic Complete CSD 2000-30000bph Production Line | PH≥4.6 CSD | |||||||

Material | Shape | Filling volume | Filling level(mm) | Neck type | ||||

PET Bottle | Square or Round Bottle | 100-2000ml | Distance from bottle neck According request | As request | ||||

Adjustable specifications of the bottle type | 【Middle Mould Base】Bottle diameter ≤105mm Bottle Height≤335mm | |||||||

Customers need to buy additional change-over parts for the different bottles. If using square bottles, then bottle separating system will be added. | ||||||||

Container Label & Control Mode | Packaging system | Palletizing system | ||||||

Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automaticc | Packing system | Min, Spec. | Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer | |||||

Manual Film shrinker Wrap Around packer Robert Packing Machine | 1*2 2*3 3*4 4*6 3*5 | |||||||

User Ambient Conditions | Temperature:0~4℃;Humidity:No dew | |||||||

User Electrical Supply Specification | Voltage:380V±5%, 3phase; Frequency:50HZ±1% | |||||||

Cooig.com で行われるお支払いはすべて厳格な SSL 暗号化と PCI DSS データ保護プロトコルで保護されています

ご注文品が出荷されていないか、行方不明になっている場合、または製品に問題がある場合は返金を請求してください

無料の部品交換および修理対応を利用できます